ASSET TRACKINGAssets are tracked continously through the production process using active tags. Passive auto-ID technologies such as barcode and/or passive RFID are a means of gathering point-in-time information on items as they work their way through the downstream supply-chain process. Combined passive and active technologies generate extremely robust and reliable layers of aggregated data that can be used to make more informed decisions about operational business processes within manufacturing and supply chain. |

ASSET LABELLINGOptimised for high-volume, mission-critical and speciality labelling applications, Zebra’s Xi™ series printers are ideal for asset management. Combining these robust and reliable printers with Zebra’s speciality supplies and ribbons allows the production of oil- and temperature-resistant labels as well as small, high-resolution labels. |

CONTINUED PRODUCTIVITYLine-side staff make a replenishment or operator assistance request from their workstation by pressing the wireless WhereCall RFID button. A small device, this can be attached to assets of many kinds such as forklifts, containers and hospital test equipment, as well as to trailers and container chassis. The WhereLan III is a state-of-the-art sensor that receives low-power signals emitted by the WhereTags, determining the time of the call request. |

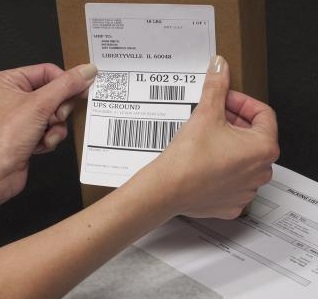

BUILD MANIFESTA build manifest allows a production line to be more efficient when completing individual bespoke orders at one time. Using handheld scanner devices, sophisticated build specifications can be quickly viewed on screen, and at each build stage, Zebra® desktop printers can quickly and accurately produce a barcode label to update and/or complete the process. Active RFID tags are added to the asset at the start of production to aid onward visibility and tracking. |